-

See the Archives

- April 2015

- March 2015

- October 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- Filter by Category

Wellhead casing project

We always have new and interesting projects come through the shop. This one was a wellhead casing project which consisted of a few tasks:

- mechanical design

- FEA (finite element analysis) testing

- CNC cutting and engraving

- TIG welding fabrication

- Powder coating

All these steps were done in house to reduce lead time and improve quality control.

Design

The design of this project was based loosely around the existing prototype developed. The prototype was quickly reverse engineered in order to have a 3D model to compare our new design against. This will allow us to compare the range of motion and limitations of the prototype vs the new proposed design. There was also a list of requirements that the new design had to achieve that the existing one couldn’t do or perform, one example is the lack of a guard on the sheave/pulley.

Here is the prototype, ready to be reverse engineered.

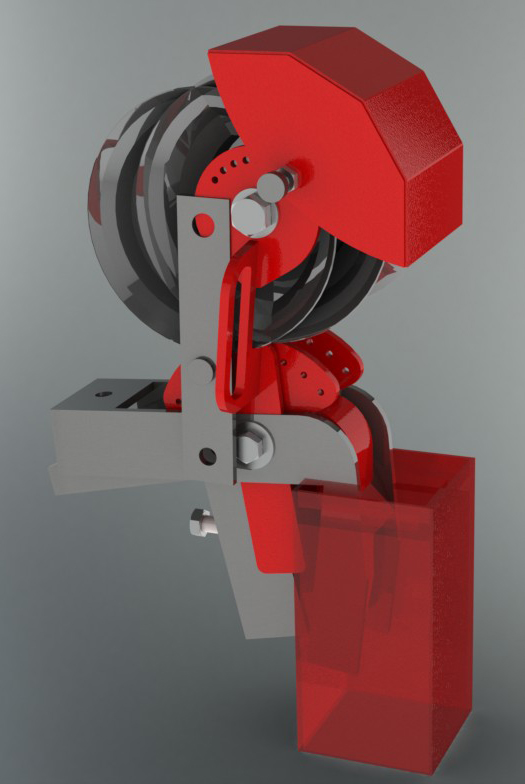

Here it is modeled up and mocked up on a small wellhead. The hardware was not modeled as they wouldn’t add any value to the new design.

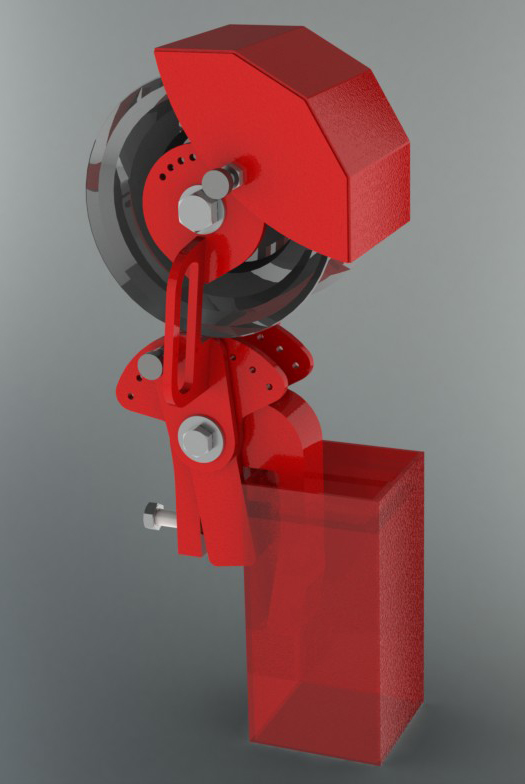

Now we began our design process taking the reverse engineered prototype into account. Here is the preliminary design compared to the prototype. The new design took requirements from the client as well as added a few other features to compact the design as well as make handling and setup easier. The handles on either side make carrying the unit easier as well as adjusting the position of the sheave. The handle is also located very near to the COG (center of gravity) of the part so it makes it very easy to carry. Here you can see the prototype and the new proposed design overlaid on top of each other.

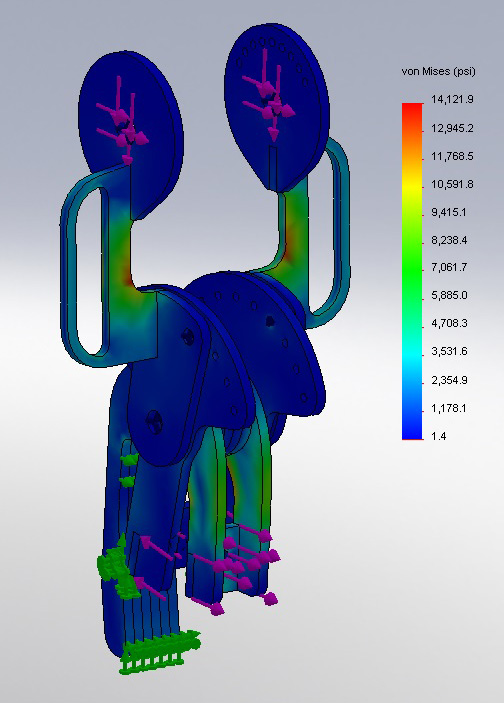

Since the functionality of the new design is different in a few ways than the prototype, it is submit for a design review and no modifications were needed. The 3D model is then set it up for FEA (finite element analysis). The initial design is to show the concept of how it will work, now with taking loads into account we can factor in how it will actually perform and meet all the requirements of the client.

Here you can see a stress concentration on the arms, this was the final design, prior to this the concentration was higher around the radius as it was tighter. Just a simple tweak in the design and we minimized this stress to an acceptable level without any real added weight.

The design could have been optimized further by reducing the material thickness of members under low stress, however the design also considers the cost of fabrication. The minor cost increase and weight to a part being thicker than necessary outweighs the cost of having to load multiple sheets of various thickness material onto the CNC table to be cut. In this case everything was designed to be cut out of 1/4″ plate except for the top of the guard which would be done out of 10ga steel (1/4″ would have made it far too heavy and cumbersome). Here is the final design mocked up.

Now that the design achieves the clients requirements and has been approved, the project proceeds to the fabrication phase.

Fabrication

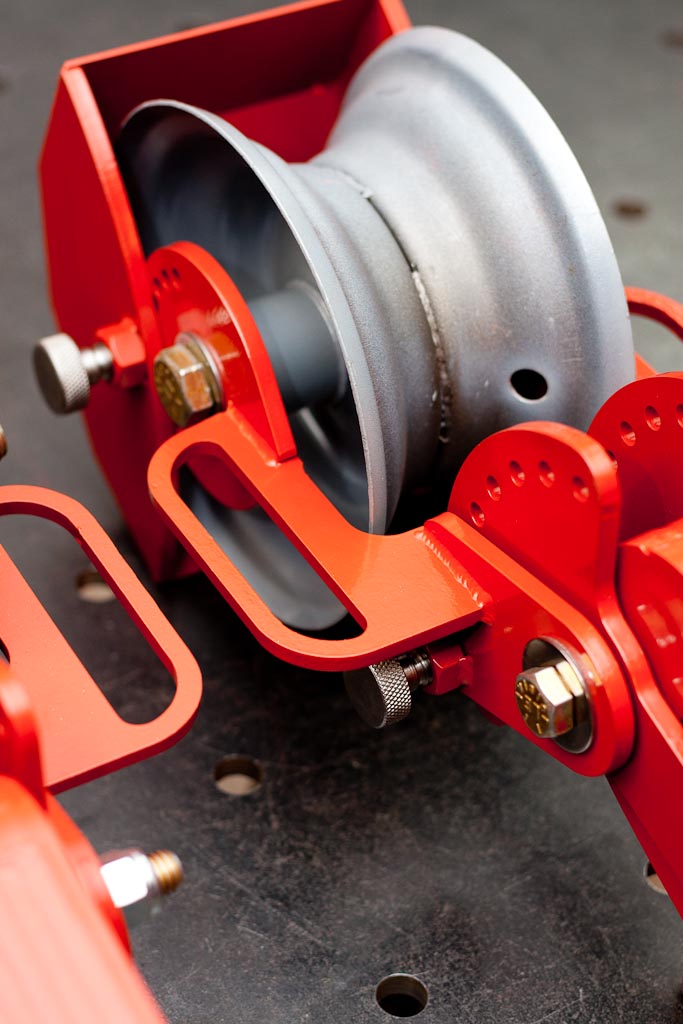

Once the design was completed all the parts were exported to our CAM software, nested and cut out of 1/4″ 44w steel plate. Hardware was brought in based on the hardware selected in the design.

Next the pieces were acid dipped to remove the mill scale to prepare it for welding and eventually powder coating. The TIG welding process does not cooperate well with burning through mill scale and it takes a tremendous amount of time to media blast mill scale off. Our in house acid bath works quick and takes little effort. The parts are susceptible to some light oxidization due to the steel being stripped bare, no protective coating is applied since it would have to be removed prior to welding and the part is going to be blasted prior to powder coating anyways.

Here the parts are being welded and tacked up.

These plates were sandwiched together and a groove was CNC cut in two locations, these locations were TIG welded to secure these pieces all together.

All the parts are 100% welded up, blasted and ready for powder coating.

These parts were powder coated with RAL 3016 Coral Red. Here is one of the arms ready to be cured in the oven.

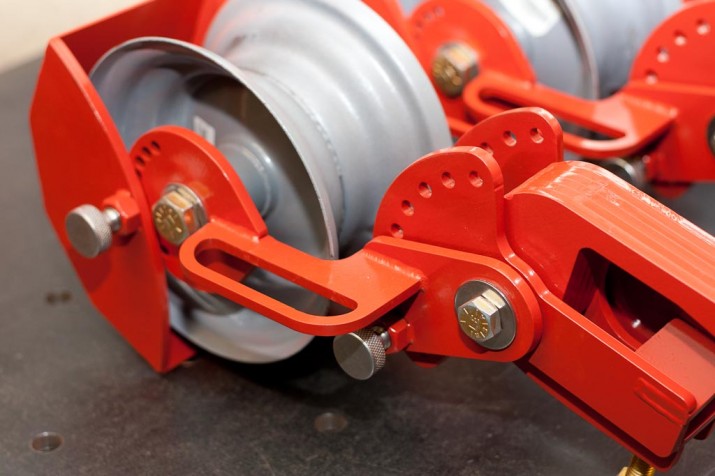

And here they are out of the oven, assembled and ready to be used.

This project started with a physical prototype and ended up with a commercial functioning/looking product. This project combined mechanical design, CNC cutting/engraving, TIG welding and our latest powder coating service. Everything with this project was done in house to reduce lead times and achieve the highest quality product for our client.