-

See the Archives

- April 2015

- March 2015

- October 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- Filter by Category

More equipment and cutting

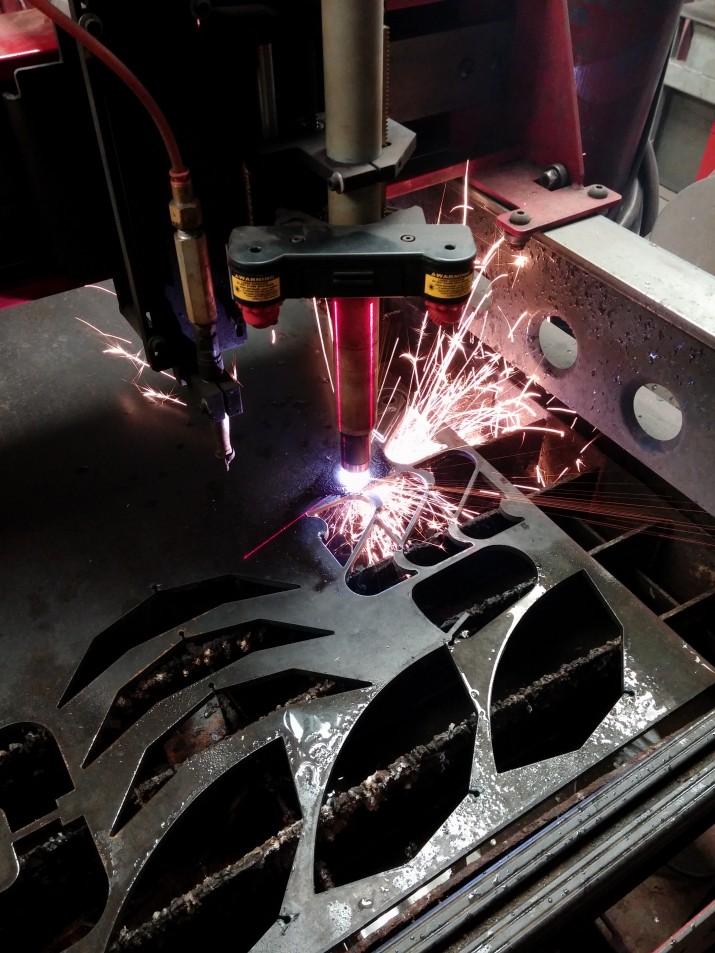

Well Mint Design has been busy in the shop immediately after New Year’s! We’ve got more equipment and cutting going on in the shop. We’ve addressed deficiencies in 2013 and taken in a lot of feedback from our clients. The three main areas were dust control (from all the bead blasting prior to powder coating), obtaining drier compressed air (to improve CNC cutting, bead blasting and powder coating) and the ability for bending CNC cut parts (long thin pieces to short thick pieces). We’re in the process of building, setting up and testing all these new pieces equipment, all while keeping our shop running and turn around time as short as possible. We’ve got a lot of things on the go! Here we are cutting some 1/4″ plate, with AVHC lockout with 60% cut speed for all the holes (results in straighter holes with less taper) and 100% cut speed with AVHC active when cutting the bend lines and perimeter. These brackets are destined for a motorcycle shop in the Saskatoon area.

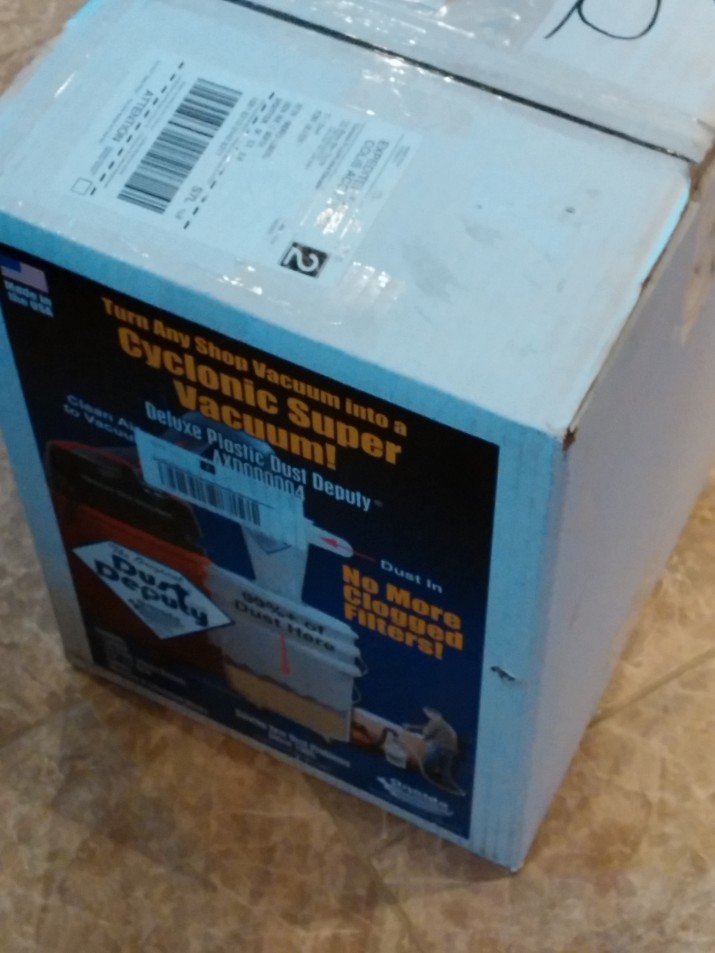

We also picked up something to reduce the dust in the shop and reduce plugging the shop vac filter with media dust from all the bead blasting. Most would use a dust collector, however floor space is a premium in our shop and the less cleaning of bags and filters the better. This dust collector uses basic centrifugal force to have the dust drop out of the air and into the bucket, with minimal dust entering the shop vac. Similar to the cyclone technology touted in Dyson’s and other bag-less vacuums, same principle just on a larger scale. This should prolong filter life and reduce the level of maintenance required. We’ll be sure to post updates once it is set up and how well it works.

And finally we had our Baileigh box and pan brake show up. Due to our small shop it took a bit of creativity, a lot of safety straps and muscle to move this 750lb unit around the shop! Thanks to the local Fastenal rep., Matt, for the patience while we unloaded it from the truck onto the hoist. It was a bit tricky without a forklift or the use of any overhead crane. After it was unloaded it was unboxed and then maneuvered into place next to the CNC table.

This box and pan brake will allow us to do 12ga at 40″ wide, anything thicker we can use our hydraulic press and other tooling to bend up to 5/8″ steel plate. Keep posted for our new bending services in the near future!