-

Archive of May, 2014

- April 2015

- March 2015

- October 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

CNC cut race tracks out of steel

This CNC cut race tracks project started as a simple request from a picture posted on a local car forum. After converting the tracks into vector format and entering in all the track names a group buy began. These are cut out of 14ga cold rolled steel. Normally hot rolled is used in our shop, but in this case the final part will have a sanded finish and having to remove mill scale from hot rolled is a time consuming process on a large part like this. Small parts aren’t a problem when they can be stripped in an acid bath.

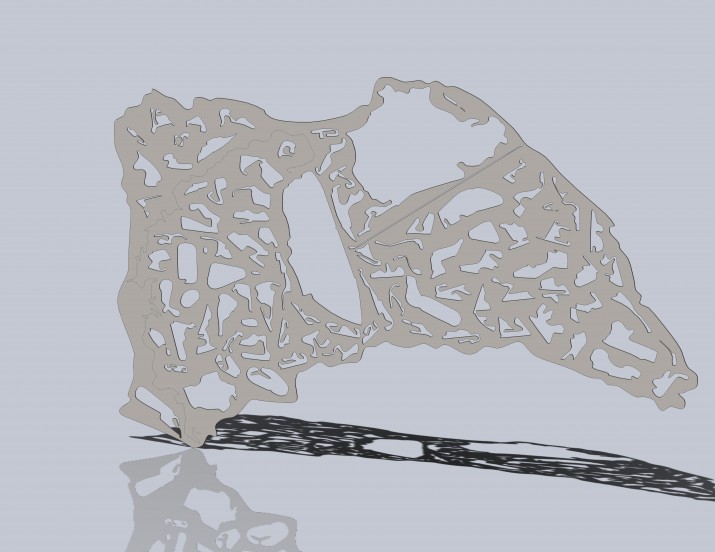

Here is the CNC cut race tracks as modeled in SolidWorks , just the plasma cutting portion.

Then the names were added next to their respective tracks. All the text will be engraved prior to plasma cutting.

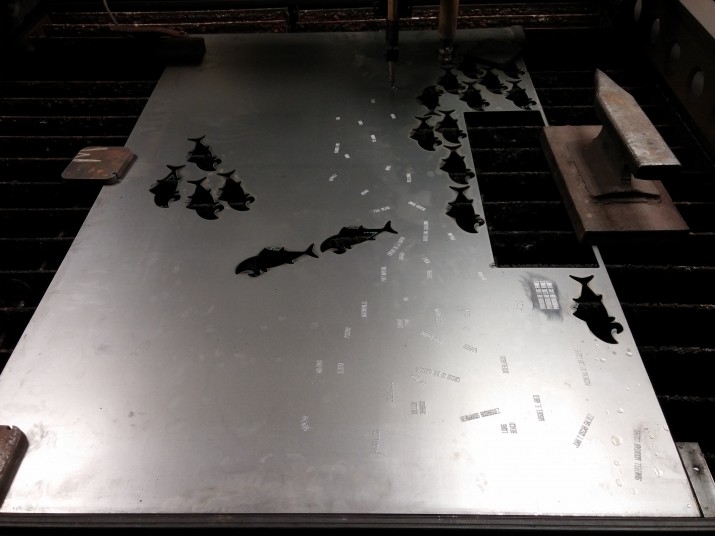

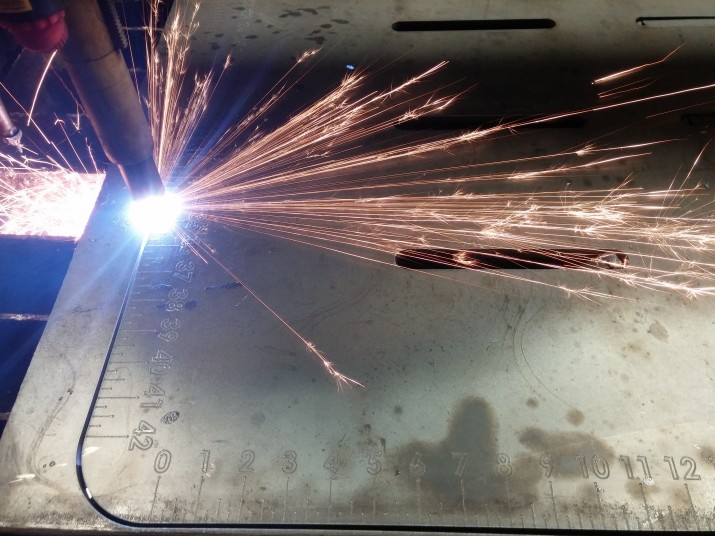

Here’s some of the engraving going on, the fish are actually bottle cap openers that are nested into the voids of the sheet. Some are even nested in the Nürburgring and in the Circuit De La Sarthe. Every square inch of material is utilized when cutting. The scuffed up metal below the rectangle is just an area for test engraving and seeing how the sanded finish would look with the engraving. The anvil and 1/2″ thick steel plates are used to keep the plate solid during engraving. We’ve never had issue with a sheet of this size moving from vibration. However with around 1/2hr of engraving time it’d be foolish not to be overly cautious.

Here’s all the parts fresh off the table. The race track and Möbius Threads sign will have a sanded/brushed finish and the fish will be going in for an acid bath to strip any oils and to easily remove any dross. The fish will be used as powder coat sample tiles. For every new powder we apply a few of these fish will be coated so we can allow customers in the future to choose a finished powder by seeing an actual sample. We have these bottle cap openers for sale. They will be limited run colors and there will be a lot of variations! This is the first batch of four to come out of one steel sheet.

Here it is the track after the sanding process and sealed with boiled linseed oil.

And a whole bunch of fish ready for a final bath in the acid before they are ready for powder coating!

Keep posted for some busy blog posts coming up! Custom electronics, sheet metal fabrication, TIG welding, polishing, powder coating and more! Be sure to follow Mint Design by clicking the “follow” at the bottom right of your browser!

Welding table top, new projects and equipment

Well it’s been a very busy couple weeks in the shop as we’ve just been busy preparing for a lot of future projects and just finishing up a few. We also have some new equipment being brought in and a really interesting project based on Arduino Uno from Newark Electronics coming up too. Here’s some of the things being worked on and a few previews of what’s coming down the pipe.

The majority of the welding done at Mint is done via TIG welding process. However we have had an increasing amount of work in the industrial sector which doesn’t require the costly TIG welding process, so we managed to pick up a MIG to speed up fabrication work. We try to buy equipment that gives us the best value and in this case it was a very lightly used Millermatic 251, it can do up to 1/2″ thick steel in a single pass and also work with a spool gun for mass production aluminum work. We don’t have any need for a spool gun just yet, but it’s always nice to have the option to easily add it on. The voltage output is not stepped so it can be infinitely adjusted and recorded if doing the same type of work over and over again. The wire feed value can also be recorded to if doing the similar type of welding, or at least the settings will get us in the ballpark quicker. This is replacing a 110v Lincoln welder, which worked great for thin sheet metal, but anything beyond that it just couldn’t cut it. Keep posted for some future projects relying heavily on this Miller welder.

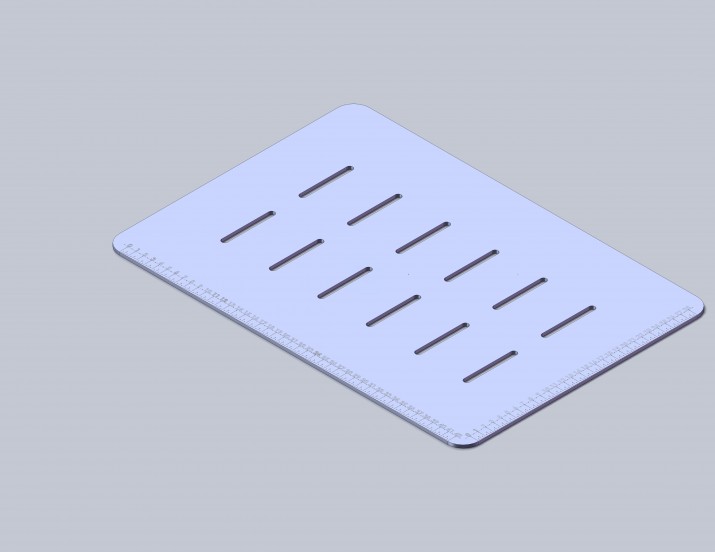

Here we’ve designed and cut out a 3/8″ 44w hot rolled steel welding table that measured 32″x46″ and weighs 150lbs. This is produced for a local fabricator who will be building the frame to go under this top. The one unique feature is the engraved ruler around two sides of the table. That way if you ever misplace a tape measure and need to get a rough 1/4″ measurement you can easily do so at the edge of the table. The table also has slots to allow for use of clamps or other fixtures while welding. Every project is very customer specific, even down to the custom chosen font. It might not seem like much, but when you’re getting something custom from Mint Design, it’s done exactly how you want, right down to the font.

This is one project that has been kept mostly under wraps for the last month and a half, it’s still a work in progress but this is the only preview we can provide. It’s a prototype, and yes it doesn’t show much. The production unit is been redesigned to be easier to manufacture and will be offered in three different powder coated colors. They’ll be ready before Fathers Day so keep posted!

A few of the other projects on the go are a custom CNC cut 1/4″ stainless steel handle on a samurai sword, some CNC cut race tracks out of 14ga steel, lots of powder coating and a fully polished 304 SS show car Cadillac exhaust system. Also an Arduino Uno (supplied from Newark Electronics) electronic/mechanical project that will be developed in the shop.

Also since getting back from Costa Rica mid-March I have been editing our trip video when I am not busy with my family or in the shop. It’s finally completed, so grab a seat and please enjoy our Costa Rica trip video until the next blog post!