-

Archive of June, 2012

- April 2015

- March 2015

- October 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

Donating plasma time for a good friend

When we’re not working we try to get down to Cabo San Lucas when possible. We have one good friend down there, Javier, who runs a very small restaurant called Gordo Lele’s. He’s been very good to us and we were donating plasma cutting time to cut some souvenirs for him to sell. All the profits were his and he sold, about $200 worth of bottle cap openers in three days, not bad for Mexico!

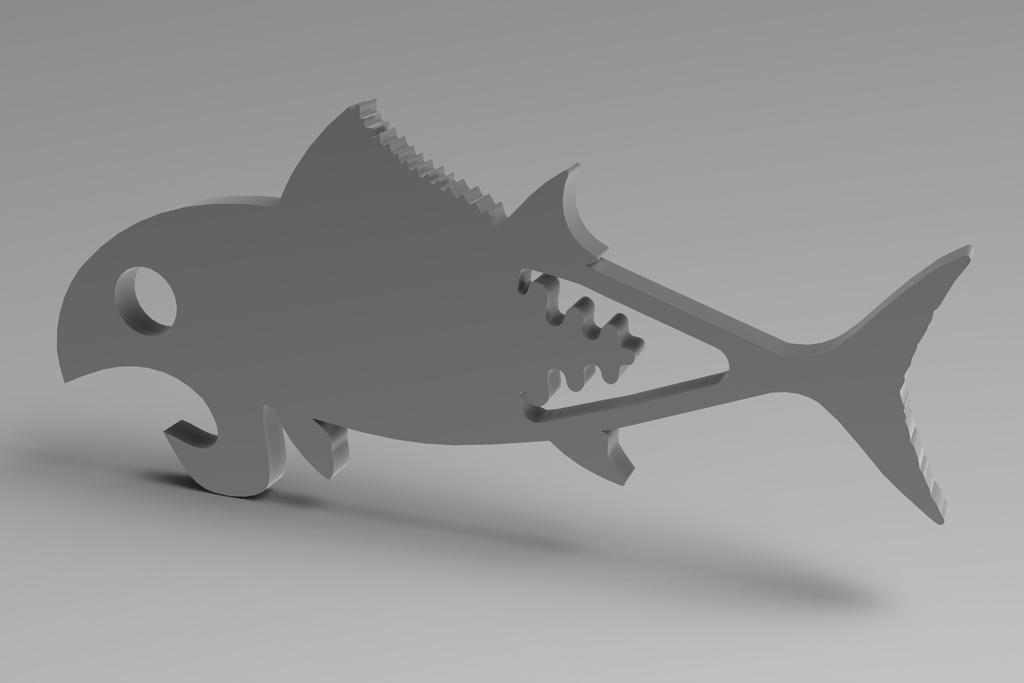

3D model.

Here are some cheap prototypes cut out of 3/16″ mild steel to get an idea of what they will look like and feel like. We also did one with some engraving to see how it’d look.

After a few tweaks (we radiused some edges as they were quite sharp) based off the prototypes the final 304 stainless steel pieces are ready to be wrapped and brought to Javier!

At Mint Design we are fortunate to have so many loyal customers and we try to give back where we can. Javier is one of those people that we just want to see succeed and this gift to him was a very good surprise. These pieces were fairly easy to make, as we could knock out hundreds of these in an hour, the only problem is that it’s heavy, and taking a lot of one type of item in your carry on to Mexico might not be the best idea. So we figured a dozen pieces will be a nice surprise and we told Javier that he should keep one for himself!

Designing a working platform

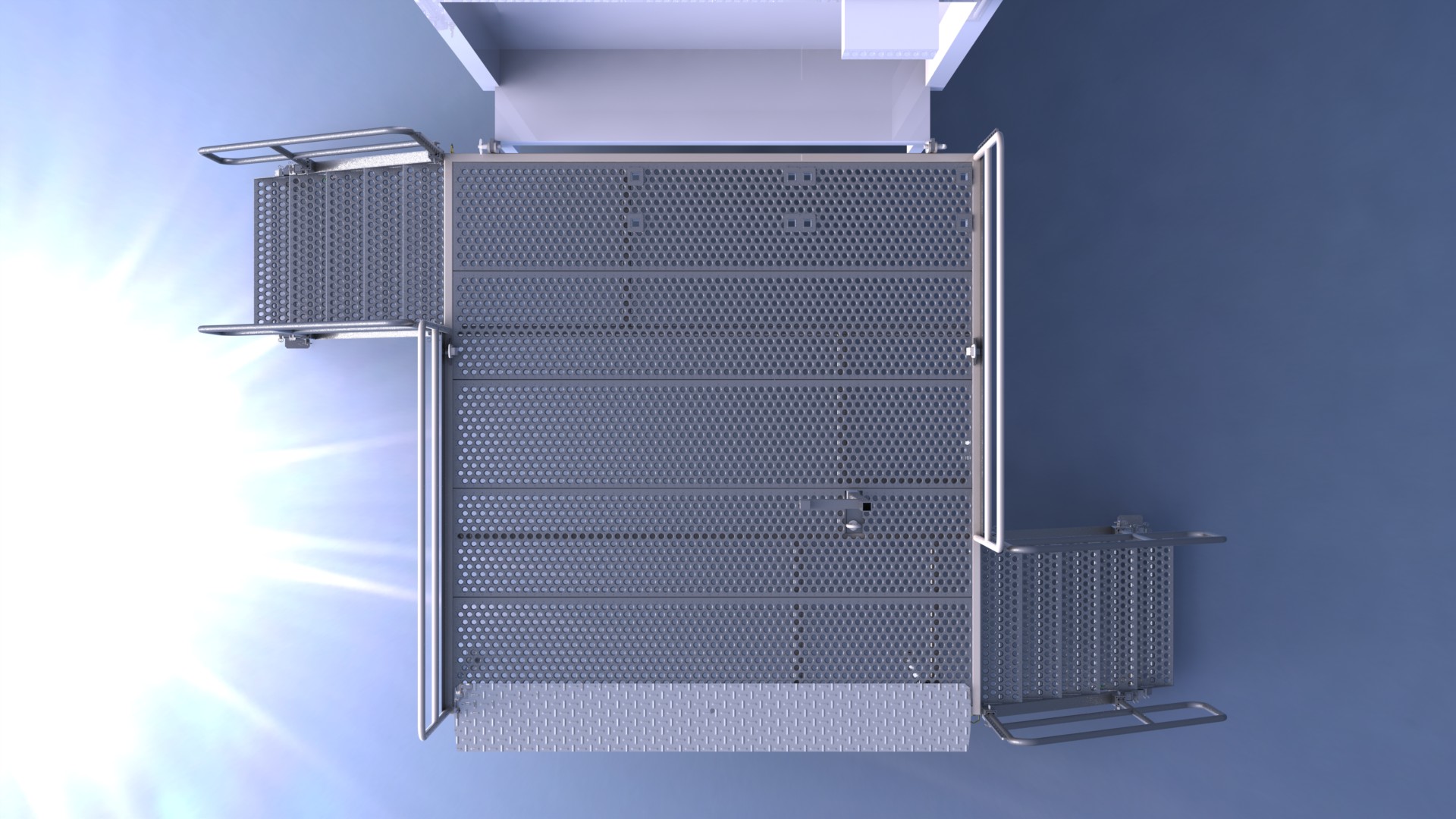

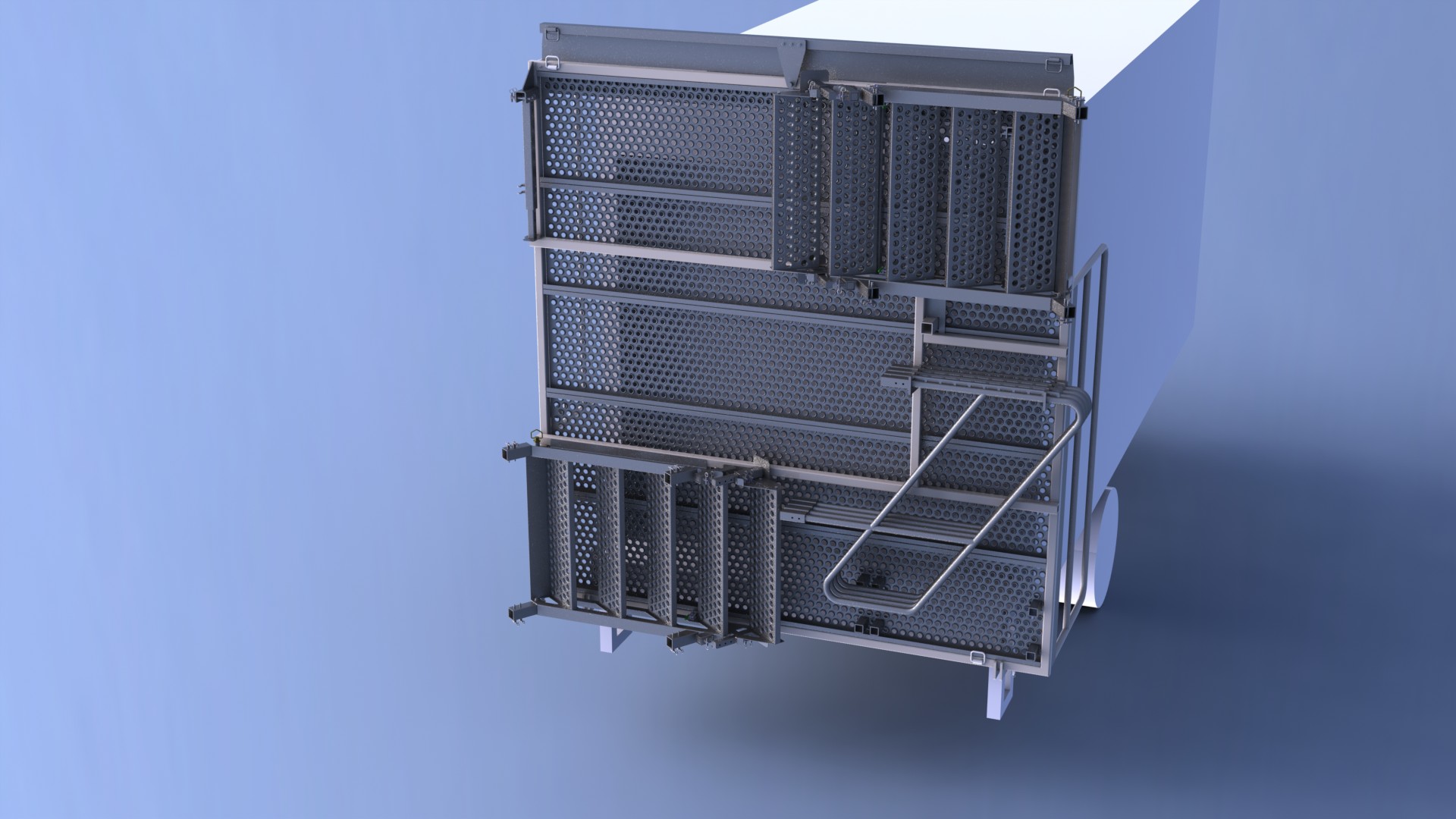

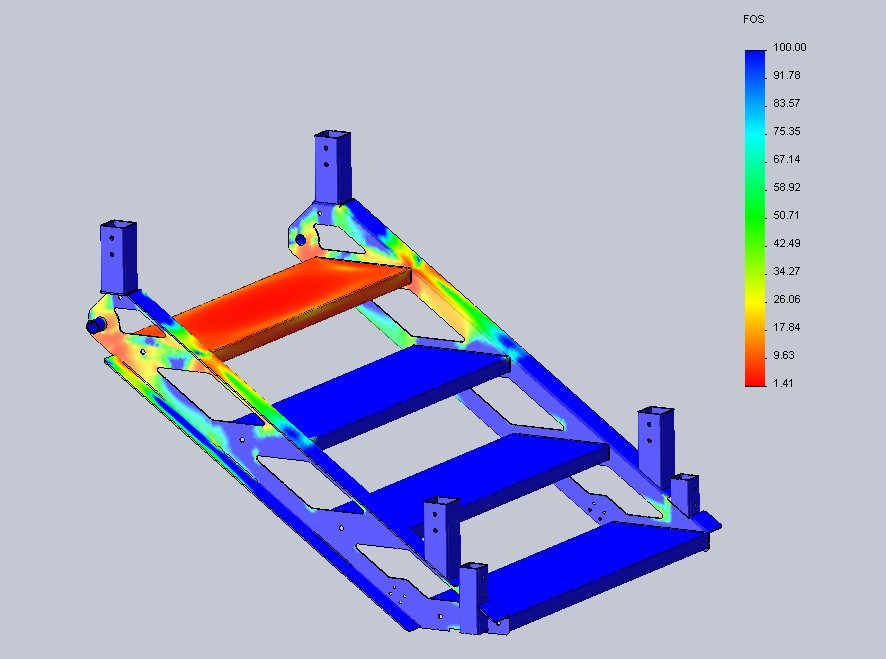

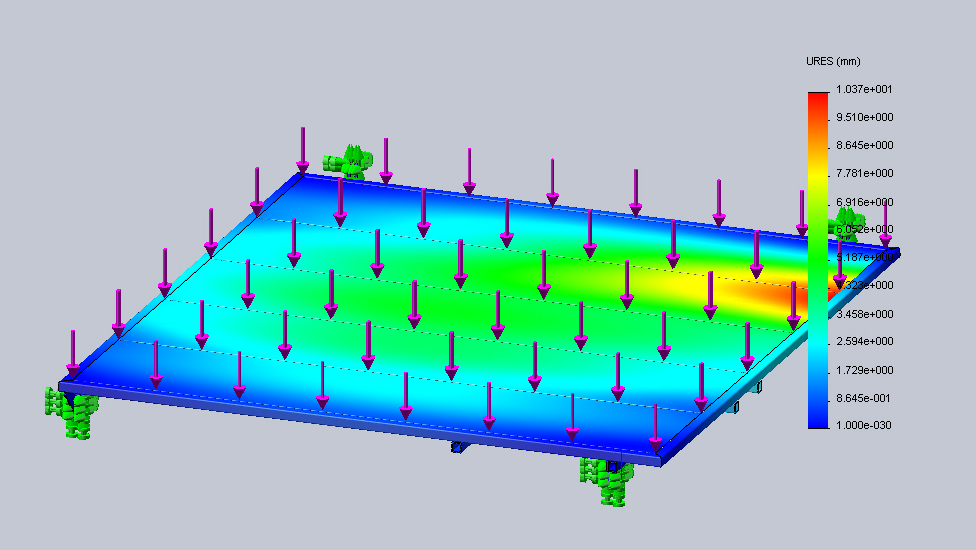

This was a pretty substantial project with a lot of constraints and requirements. Designing a working platform to be modular, strong/durable and easy to replace out in the field was the major requirements. Our customer, Cross Borders Consulting, is 2-1/2 hours away so after a one day trip measuring out everything we needed the design work began. The list of requirements were noted, OH&S guidelines reviewed and we began sketching out some ideas. After the design review a few modifications were made, FEA was completed and the drawings were produced. The stairs were the trickiest part, as it had to be adjustable in height, since the platform can be raised or lowered 12″ (in 1.5″) and the stairs had to accommodate that amount of travel and still meet OH&S guidelines with still being functional, hence the add on step. And they also had to collapse underneath the deck while in transport, which was tricky on the passenger side due to the leg that collapsed under the step. Also when the platform is in it’s lowest position there are two steps that drop into place that allow a step up from the platform into the back of the truck, all meeting OH&S requirements. Here is the final product.

3D model.

FEA testing.

And the final product (built by the customer based off our drawings).